Sample Products by Their Processess

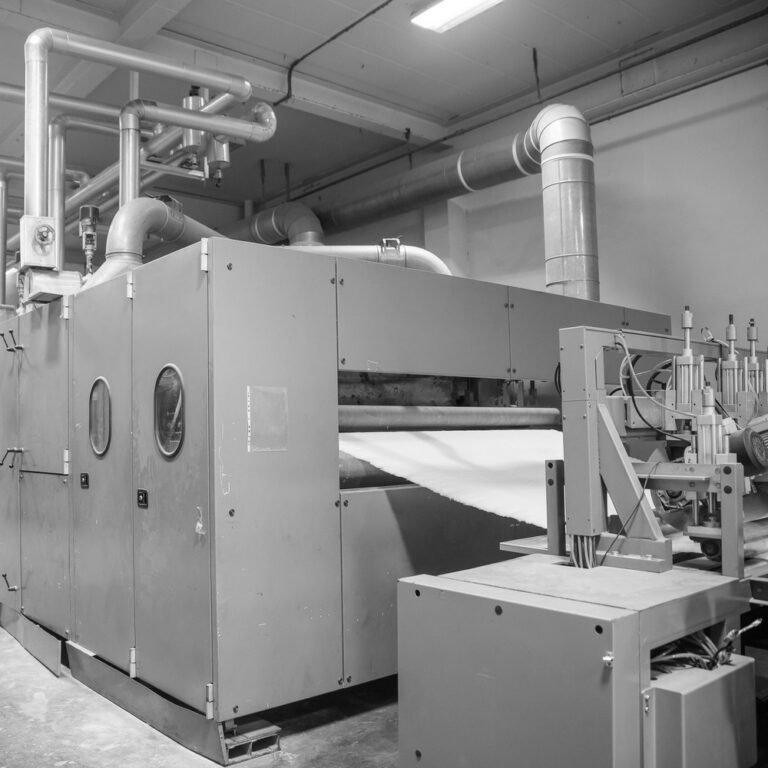

Needle Punch

A needle punch insulator is a type of nonwoven fabric that’s been mechanically interlocked by needle punching. This process involves barbed needles repeatedly punching through a web of loose fibers, entangling them into a more cohesive and compact mat. The result is a durable fabric with excellent insulation properties, often used for thermal and acoustic applications in various industries, including automotive and construction.

The needle punch technique allows for the creation of fabrics with specific characteristics by adjusting factors such as fiber type, density, and bonding patterns. This versatility makes needle punch insulators a popular choice for products like oven mitts, casserole warmers, automotive insulation, and even specialized apparel.

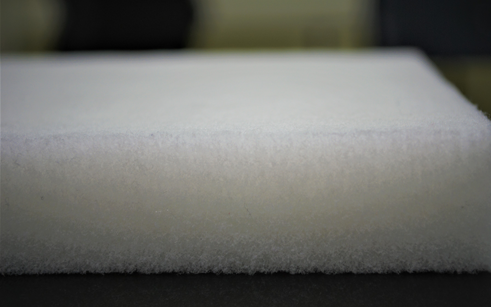

Vertical V-Lap

The term “V-Lap insulator” refers to insulation materials produced using the V-Lap process, which is a method of vertically lapping fibers to create nonwoven fabrics with superior thermal and acoustic insulation properties. These materials are known for their straight-up fiber structure, which contributes to their effectiveness as insulators. The V-Lap process is designed to be cost-effective, with modest capital costs and low energy consumption, and it can work with a wide range of fibers, both man-made and natural.

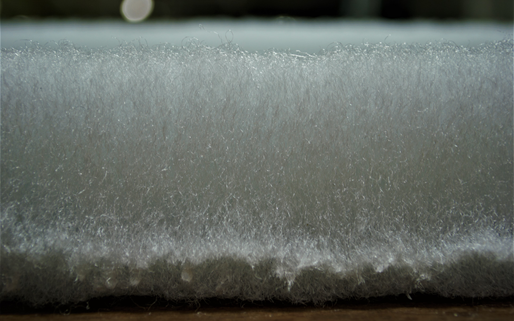

Thermobond Felt

Thermobond felt refers to a type of nonwoven material that is created by bonding fibers together using heat. Thermobond nonwovens are produced by mixing chopped fibers in a silo. These fibers are then carded into wadding. As the material passes through thermal rollers, it is melted together using heat. The result is a nonwoven fabric with specific properties.

It is a versatile nonwoven material with various applications, especially in absorbent and cleaning-related contexts.